Interface level measurement

Mixing application versatility with proven results – no matter the industry

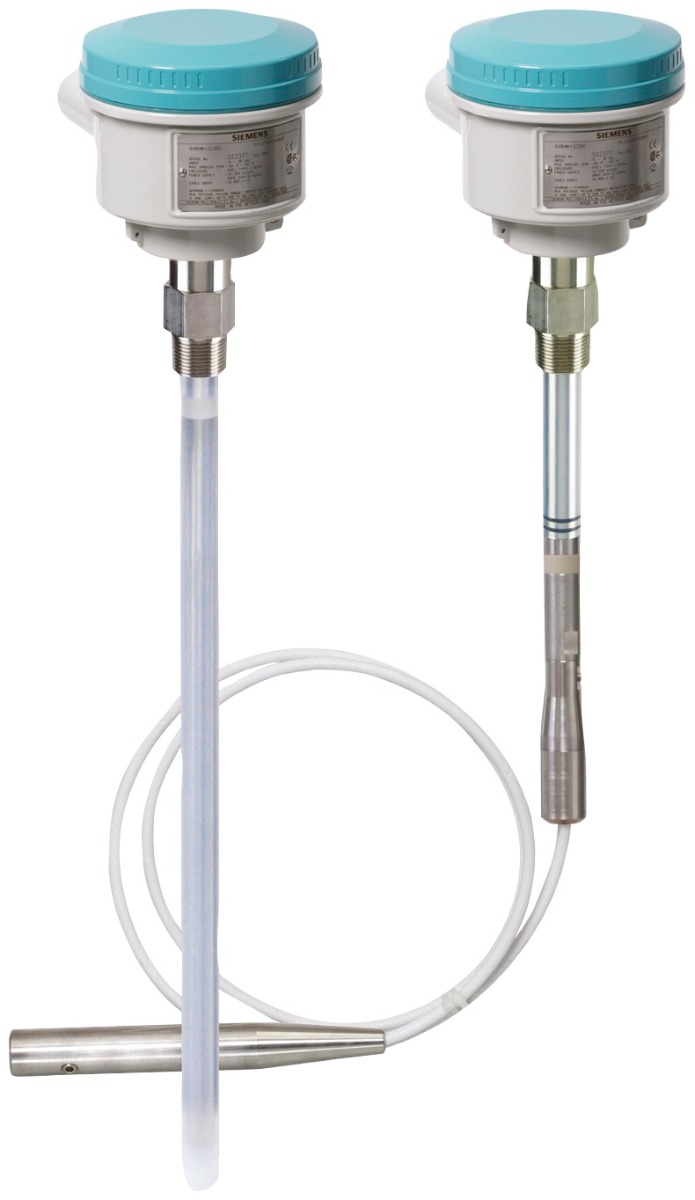

Whether it’s water and oil or two wildly different chemicals, some things just don’t mix. Luckily, Siemens interface technology measures level of multiple materials with ease and precision. Capacitance and guided wave radar technology provide results-driven level measurement in all your interface applications, giving you the accuracy and continuous monitoring to keep operations running smoothly throughout the day.

Point level or solids interface - vibrating

Continuous interface or level - capacitance

Continuous interface and level - guided wave radar

Interface level measurement

Interface measurement easily handles changing pressure and temperature conditions and is unaffected by vapor or condensation. Whether measuring levels of two materials in a storage vessel or telling your control system when to separate one liquid from another, accurate monitoring helps ensure product quality and an efficient process.